Supply Chain Management

Importance

Responsible supply chain management is an essential factor in the efficient delivery of goods from production processes to consumers. Therefore, the Company places importance on management, from selecting potential business partners, providing an assessment and traceability, and covering diversity and equality, such as doing business with suppliers whose business owners are women and vulnerable communities, such as people with disabilities, as well as integrating sustainable development practices into business operations and taking into account social, environmental and corporate governance issues throughout the supply chain to increase opportunities, reduce risks and enhance the competitiveness of the business, and strengthen business partners and business alliances sustainably.

Target and Performance

| Indicators | Target (Percentage) | 2024 Performance |

|---|---|---|

| Tier 1 Suppliers who were communicated Supplier Code of Conduct and Guideline | 100% | 100% |

| Tier 1 Suppliers signed acknowledgement Supplier Code of Conduct and Guideline | 100% | 100% |

| Significant Tier 1 suppliers were assessed for environment, social and governance (ESG) risk in their operating sites. | 100% | 85.71% |

In 2024, the results of the environmental, social, and governance (ESG) self-assessment from suppliers and the ESG risk assessment in the operation areas found “no risk”.

Supply Chain Management Policy

The Company has set the purchasing policy of Sri Trang Group to conform with the social responsibility policy and strictly adheres to the business code of conduct regarding trading partners and competitors to prevent monopoly, unfair competition and corruption, and to generate new sellers by establishing working guidelines for the organization and selecting running the business with partners who are socially responsible, such as green procurement, buy energy-saving equipment, have a non-child labor force, no forced labor or slave labor, no violation of human rights, fair employment, and common care of the environment as well as promoting knowledge and understanding for partners to be socially responsible. In the systems of ISO9001, ISO 14001, ISO 45001, and BSCI Code of Conduct, there is a supplier assessment covering social and environmental aspects while working in the Company’s area and annual evaluations.

The Company prepared a Business Partner Code of Conduct and Guidelines to promote business partners to conduct business in a sustainable manner and in accordance with the Company’s business practices. The Company refers to the charter and standards recognized internationally, such as the International Labor Organization (ILO) and the United Nations World Agreement (UN Global Compact).

Supplier Code of Conduct Sri Trang Agro-Industry Public Company Limited

Credit Term with Suppliers

The Company places importance on assigning credit to each supplier to ensure sustainable growth in collaboration with partners within the supply chain, delivery of standardized products on time and business ethics. The credit terms should reflect both the creditworthiness and liquidity management capability of the Company and suppliers. Generally, the credit term of the Company with suppliers are within 30 days.

| Credit Term | Average Credit Term in 2024 |

| 30 Day | 26 Day |

Supplier Management

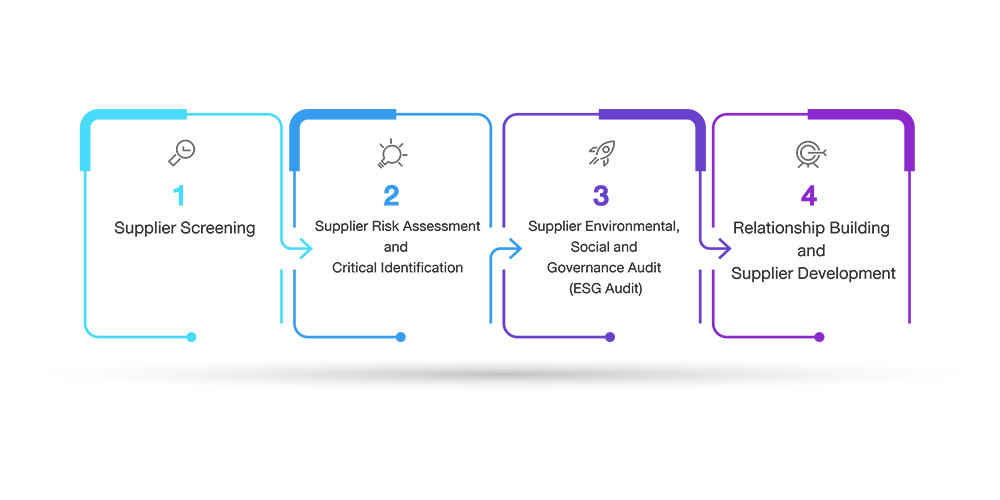

The Company is aware of sustainable supply chain that is applied environmental, social and governance practices (ESG) integrate to supplier management approach with a focus on transparency and accountability throughout the process, as follows:

1. Supplier Screening

The Company will assess and choose them by using the assessment criteria that cover social standards, such as labor, safety, environment, governance (ESG) and business continuity management.

2. Supplier Risk Assessment and Critical Identification

The Company has set criteria for assessing the importance of critical Suppliers and ESG risks in order to group suppliers according to their risks. by considering the characteristics of products and services provided by partners Analysis of procurement costs in each group of goods and services Trading partner classification criteria have been established. in order to be able to manage business partners appropriately Can be divided by type as follows

The Company has established criteria for assessing the critical suppliers and ESG risks, with the aim of categorizing suppliers based on their risks. These criteria take into account the characteristics of products and services provided by suppliers, as well as the analysis of procurement costs for each group of goods and services. Additionally, classification criteria for suppliers have been set up to ensure appropriate management of suppliers. The criteria for suppliers can be divided into the following types:

- Tier 1 suppliers are suppliers who produce or provide services directly to the Company.

- Non-Tier 1 Suppliers are suppliers who produce or provide services to the Tier 1 suppliers.

- Significant Tier 1 Suppliers are critical suppliers who produce or directly provide services to the Company.

- Significant Non-Tier 1 Suppliers are critical suppliers who produce or directly provide services to the critical Tier 1 Suppliers.

3. Supplier Environmental, Social and Governance Audit (ESG Audit)

The Company will conduct on-site audits of suppliers together with relevant departments such as the Engineering Department, Quality Department, and Safety Department. The frequency of these audits is at least once every 2 years, covering social, environmental, and governance issues.

4. Relationship Building and Supplier Development

After the ESG Audit process, if it is found that any business partner has a high risk, the Company will proactively conduct an audit of the business partner to ascertain the real risks and prepare corrective action plan to follow up on corrective actions of suppliers as well as provide training, knowledge, and advice for business partners to understand and that can be put into practice to reduce risks in business operations.