Our Rubber PLANTATIONS ARE WELL MANAGED BY A TEAM OF HIGHLY EXPERIENCED SPECIALISTS

Our rubber plantations located in many provinces in the northern and northeastern regions of Thailand. Having our own rubber plantations facilitates the procurement of raw materials, enabling better cost control and affording us increased profitability. Additionally, the plantations themselves also yield a high rate of return. Moreover, at the end of the latex-producing cycle, the rubberwood can be sold to manufacturers of furniture and pallets.

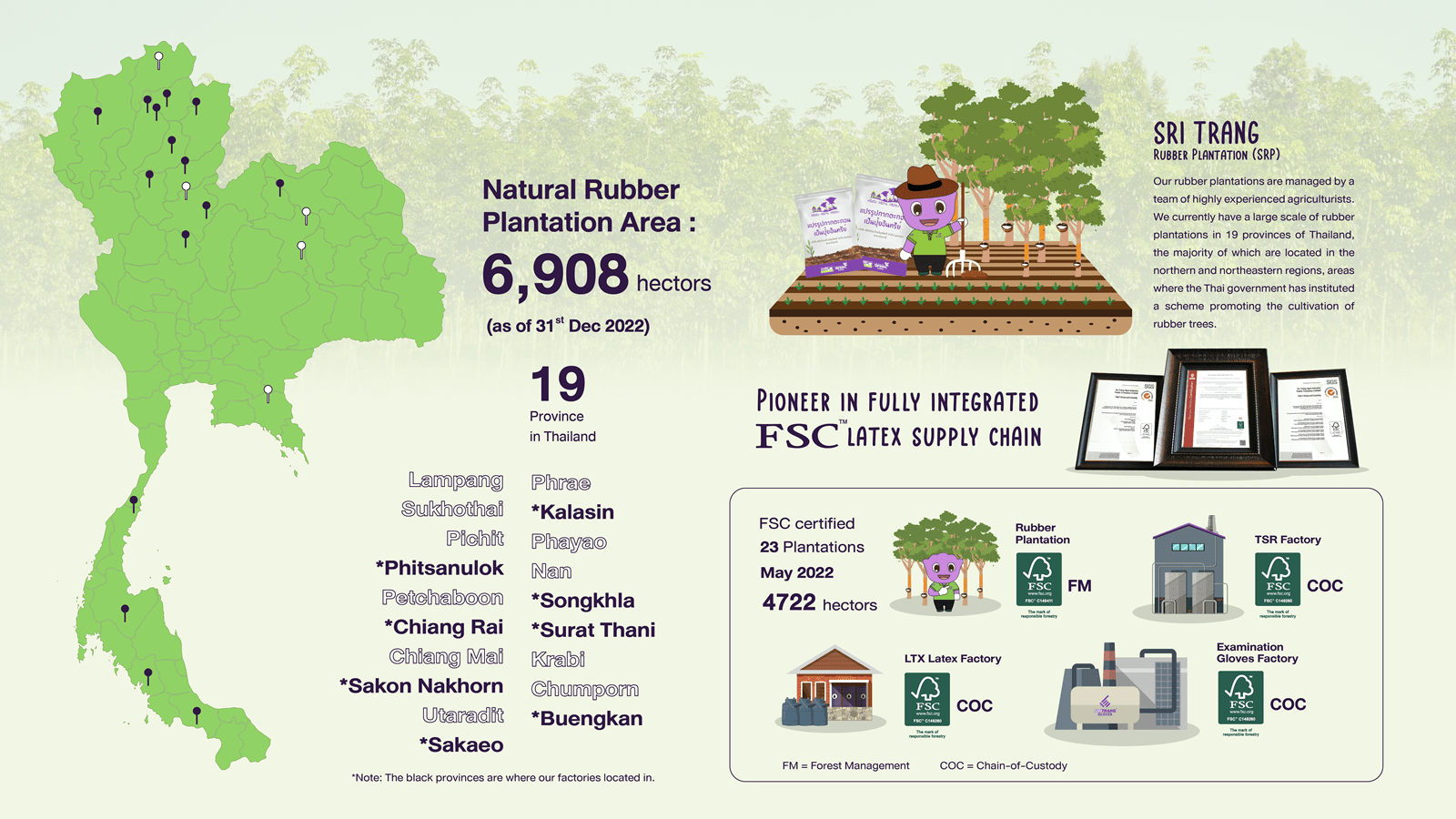

SRP Plantations Overview

| Area | |

|---|---|

| Plantation land | 7,687.88 ha |

| Rubber plantation land | 6,819.68 ha |

| Unplanted area (areas designated for future planting) | 0 ha |

| Economic crops | 832.96 ha |

| Conservation set-aside area, including HCV area | 15.68 ha |

| Conservation set-aside area, including HCV area | 0 ha |

Remark: Information as of December, 2024

SRP Certified Forest Stewardship Council Since 2019

- The Company is aware of the importance and is committed to conducting business with caution on the potential impacts on the community, ecosystem and biodiversity.

- No planting on peat.

- The company has certified 4,722 ha out of 6,908 ha (65%).

Caution on the potential impacts on the ecosystem and biodiversity.

Chemicals Used

| Fertilizers | Herbicides | Fungicides |

|---|---|---|

| N-Urea | Glyphosate | Mancozeb |

| DAP (Di Ammonium Phosphate) | 2-4 D (L) | Sulfur |

| Potassium Chloride (kg) | Copper Oxychloride | |

| Organic Fertilizer |

- The Company and all suppliers no use of paraquat (The Ministry of Industry published its notification to ban the domestic use of paraquat and chlorpyrifos in agricultural production on May 15, 2020, with an effective date of June 1, 2020).

- The Company no use WHO Class 1A and 1B pesticides.

- The Company no use of chemicals listed under the Stockholm Convention and Rotterdam Convention.

EVERY STEP OF THE PLANTING AND CARE OF RUBBER TREES

Cultivation Process

Every step in the cultivation of rubber trees is carried out with meticulous care.

Land Selection

We have placed an emphasis on land selection, ensuring that every plot of land has been lawfully acquired and is entirely unencumbered

Operating rubber plantations is a long-term investment. Rubber trees have a gestation period of about 7 years, only after which time can harvesting begin. And their tapping period, during which latex can be extracted, lasts about 25 years. Accordingly, we have placed an emphasis on land selection, ensuring that every plot of land has been lawfully acquired and is entirely unencumbered. In order to ensure the optimum growth of rubber trees, we also conduct a soil test and take account of the climatic conditions and yearly precipitation.

Selection of Rubber Saplings

Only high quality rubber saplings are selected for the plantations

Rubber trees that are grown from high-quality rubber saplings require a shorter gestation period and produce higher latex yield. Therefore, we also have our own nurseries where rubber saplings are cultivated. Only rubber saplings that are of high quality are selected for the plantations. Having our own nurseries not only ensures that we will have an adequate amount of rubber saplings to meet our yearly rubber tree planting target, it also helps to reduce costs and facilitates the supply of high-quality latex to our rubber processing plants.

Plantation Management

Team of experienced agriculturists

The management of our rubber plantations is conducted in accordance with the principles suggested by the Department of Agriculture. Each and every plantation has a team of experienced agriculturists who are responsible for all aspects of the care of rubber trees, from the watering to the application of fertilizers to the seasonal soil adjustment. In addition, we have made use of various technologies that help to increase the efficiency of plantation management. For instance, we have employed the drip irrigation method in plantations that are located in an area with a dry climate or very small amount of yearly precipitation. This ensures that the rubber trees will receive an adequate amount of water and also helps minimize the use of labor.