Napier Grass Energy Crop Project for the Community (Continuing Operations)

Introduction to the Project

To enhance the efficiency of sustainable water resource management, the Sri Trang Group has implemented the reuse of treated wastewater by using it to irrigate grass cultivation areas during the dry season. This practice helps reduce the volume of water in the treatment ponds and prepares the system to better accommodate increased water inflow during the rainy season and rubber processing period.

The company has also utilized unused land within the factory premises by initiating a project to cultivate various Napier grass varieties, such as Pak Chong 1, Israeli Sweet Grass, and Dwarf Napier. Additionally, excess sludge from the wastewater treatment system is used as a soil conditioner to promote healthy and effective plant growth.

This project serves as a model for resource efficiency, reducing environmental impact and creating opportunities for community engagement and participation.

Community Engagement in Project Implementation

Sri Trang Agro-Industry Public Company Limited, Kalasin Branch, has collaborated with representatives from nearby communities located within a 5-kilometer radius of the factory namely Ban Kham Mek, Ban Non Thong, Ban Nong Phai, and Ban Khok Kwang to implement the "Napier: Community Energy Crop" project. The objective of this initiative is to support the distribution of Napier grass to local communities for use as feed for cattle and buffalo. This promotes sustainable livestock farming among local farmers, helps reduce animal feed costs, and enhances opportunities for income generation.

The project implementation consists of the following key steps:

- Target Area Selection / Member Recruitment

In collaboration with community leaders and farmers in each area.

- Provision of Napier Grass Varieties

The company supplies high-quality Napier grass varieties to participants.

- Training and Knowledge Transfer

Farmers are trained in proper techniques for planting, caring for, and harvesting Napier grass.

- Ongoing Monitoring and Consultation

Continuous support is provided to ensure farmers can fully benefit from this energy crop.

In addition to providing a new source of animal feed for local farmers, this project also promotes the efficient use of factory resources in collaboration with the community. It aligns with the company’s long-standing commitment to sustainable development.

1) The factory cultivates Napier grass using a ridge-planting method across 25 rai of land (approximately 9.9 acres), with each participating villager allocated 2 ridges according to their registration.

2) Registered community members are responsible for maintaining their own Napier grass plots, while the factory provides water according to a set schedule.

3) The factory conducts random tests to assess the nutritional value of the Napier grass. The evaluation of roughage quality for ruminants commonly includes indicators such as NDF (Neutral Detergent Fiber) and ADF (Acid Detergent Fiber), ensuring the community can confidently use the grass as livestock feed.

The analysis of two Napier grass samples, conducted by the Research and Development Center for Ruminant Feed Standards in Khon Kaen Province, is shown in the table below. The results indicate that the samples had a Neutral Detergent Fiber (%NDF) content exceeding 50%, suggesting a high proportion of digestible carbohydrates for ruminants. Additionally, the Acid Detergent Fiber (%ADF) content was not excessively high, indicating good digestibility of the forage.

In conclusion, the Napier grass cultivated by the factory contains a moderate level of fiber-based nutrients, with relatively good digestibility, though the nutrient content is not considered very high.

| Sample type | On dry matter (%) | |

|---|---|---|

| NDF (%) | ADF (%) | |

| Tai Khuean Napier Grass, 30 Days Old | 54.6 | 28.9 |

| Pak Chong 1 Napier Grass, 30 Days Old | 62.5 | 39.2 |

4) The factory opens the Napier grass fields on a scheduled basis (three times a week Monday, Wednesday, and Friday) to allow local residents to harvest the grass. The harvested quantities are recorded and summarized in the system.

Project Outcomes for the Community in 2024

- 120 community members participated in the project as registered members.

- The company supported the community with a total of 198,549 kilograms of Napier grass, helping reduce household expenses on livestock feed. This equates to a cost saving of 794,196 THB, (based on a local market price of 4 THB per kilogram of Napier grass in Kalasin Province).

Project Outcomes for the Company in 2024

- A total of 1,071 cubic meters of treated wastewater was reused and removed from ponds, creating additional capacity for incoming water during the rainy season.

- The company reduced the disposal of 477 cubic meters of excess sludge from the wastewater treatment system, equivalent to 166.95 tons, resulting in cost savings of 667,800 THB (based on industrial waste disposal service rates of 4,000 THB per ton, excluding transportation costs).

- Napier grass aged 60–90 days, reaching a height of approximately 2.50 to 3.00 meters, acted as a windbreak, helping to mitigate the intensity of odors from the factory.

- The project positively shifted community perceptions about the factory’s wastewater. Residents expressed increased confidence in the quality of the treated water.

Project Monitoring and Evaluation

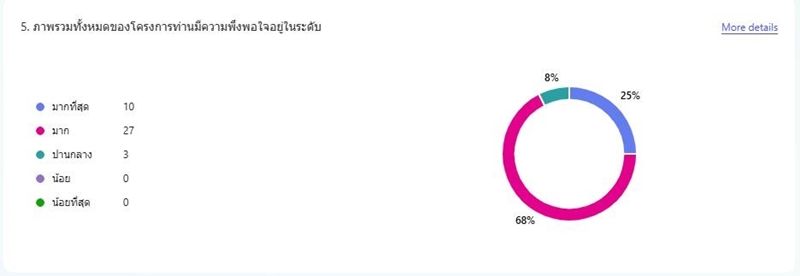

The company has continuously monitored and evaluated the project. In 2024, on-site visits were conducted to follow up with and support participating farmers. Additionally, an online questionnaire was distributed to assess stakeholder satisfaction with the project.

The results showed that the majority of respondents were "very satisfied" to "extremely satisfied" with the overall project, accounting for 93% of all respondents.

Details of the survey results are shown in the accompanying graph.