Sustainable Water Management

Currently, water-related risks have intensified due to climate change and the increasing demand for water driven by population growth and industrial development. The company recognizes the potential impacts of these risks on its business operations, including risks related to water quantity and quality, regulatory changes and pricing structures, as well as stakeholder conflicts arising from water usage. In response, the company is committed to implementing appropriate preventive and mitigation measures aligned with Sustainable Development Goal 6 (SDG 6) and Thailand’s 20-Year Water Resource Management Master Plan

Management Guidelines

3Rs

to reduce water consumption in each process with

Water Resource Risk Management

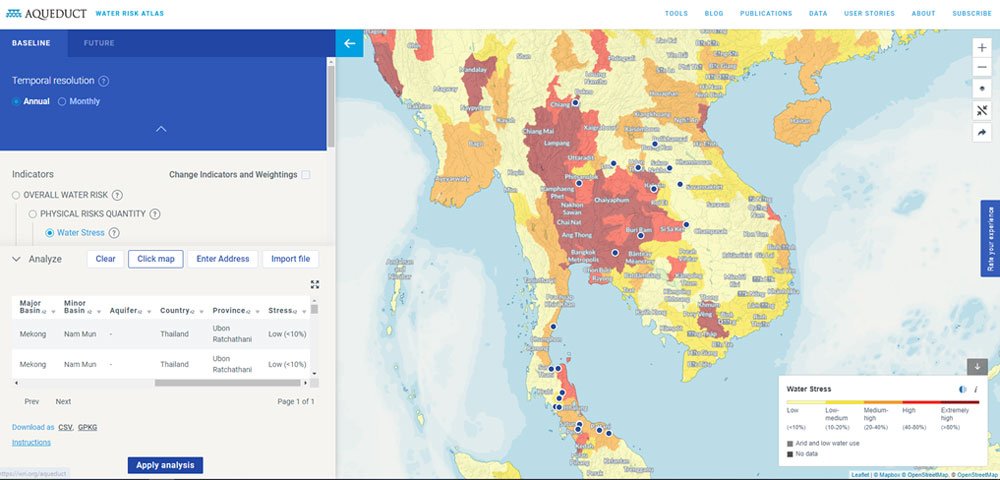

The Company has analyzed the situation of water sufficiency (water-stressed areas) in all factory areas annually using the Aqueduct Water Risk Atlas tool of the World Resources Institute (WRI). In 2024, the results of the risk assessment found that 21 percent of the production areas were in areas with extremely high of water stress, while 8 percent of the operational areas were at high risk level of water stress.

The use of the Aqueduct Water Risk Atlas tool to assess water stress risks in the company’s production areas

The proportion of areas at risk of water stress.

(The detail can be found in the 2024 Sustainability Report under the section on Sustainable Water Management)

Goal

Performance

| Indicators | Unit | 2022 (Base year) |

2023 | 2024 |

|---|---|---|---|---|

| New water withdrawals from water sources per product unit (surface water, ground water, tap water) |

cubic meters per ton of product | 1.62 | 1.46 | 1.11 |

| Percentage of water withdrawal intensity reduction compared to base year | Percent | 46 | 10 | 31 |

Wastewater Management

Management Guidelines

There are 2 types of treatment systems used as follows:

1. Aerated Lagoon

2. Activated Sludge

Maturation Pond

Goal

Performance

The block rubber factory

Concentrated latex factory

In 2024, the company had no incidents of non-compliance with regulations related to the quality and quantity of wastewater discharged outside the factory.

| The quality of effluent discharged from the factory | 2022 | 2023 | 2024 | Standards* |

|---|---|---|---|---|

| BOD (mg/l) | 6.8 | 6.5 | 5.2 | 20 |

| COD (mg/l) | 66.6 | 54.0 | 54.0 | 120 |

| SS (mg/l) | 10.3 | 15.3 | 26.2 | 50 |

| pH | 7.2 | 7.7 | 7.7 | 9.0 |

| TDS (mg/l) | 1,603.0 | 1416.7 | 989.5 | 3,000 |

| Oil & Grease (mg/l) | 1.0 | 1.0 | 3.7 | 5.0 |

Note: *Based on the 2017 Factory Wastewater Discharge Standards issued by Thailand’s Department of Industrial Works (DIW).