Policy and Commitment

The company has implemented R&D projects that cover all product groups, including block rubber, smoked sheet rubber, concentrated latex, and rubber glove products. These projects focus on enhancing the efficiency of production processes and improving product quality to meet customer demands and support sustainable environmental management. This approach leads to increased opportunities and competitiveness. The company has established a research and development policy with three main objectives as follows:

To enhance STA competitiveness

(to increase productivity and reduce cost)

To promote the sustainable and

environmentally friendly operation

To create business opportunities and

support new businesses

Research and Development Policy

(Additional Details)Goals

Number of innovations in energy,

production process, products and sustainability

at least

at least

5 cases/year

Performance in 2024

| Innovation Development Projects in 2024 | Projects |

|---|---|

| To enhance STA competitiveness (to increase productivity and reduce cost) | 5 Projects |

| To promote the sustainable and environmentally friendly operation | 6 Projects |

| To create business opportunities and support new businesses | 0 Projects |

| Total Projects | 11 Projects* |

| Total R&D expenses in 2024 | 10.56 million Baht |

Remark: *The number of consecutive projects from the previous year is 7 projects.

Outstanding innovation examples

Innovation in artificial intelligence development for natural rubber

In 2024, the Sri Trang AI Machine (SAM) project was further developed with the objective of utilizing digital technology to transform work processes. Artificial Intelligence (AI) was developed to create an automated control system in the rubber block production process, used in analytical and decision-making processes to enhance product efficiency and save energy in production. Examples include the AI DRYER, an artificial intelligence system for controlling the drying of rubber blocks in factories, and the AI Vision Camera Detection, an artificial intelligence system for quality inspection in rubber block production.

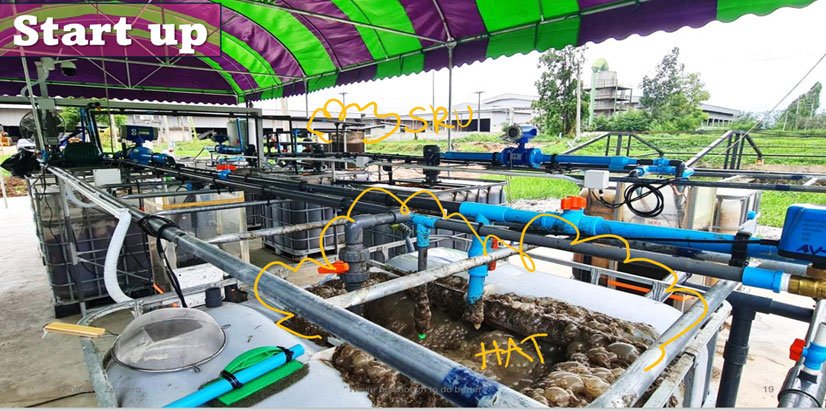

The pilot project is the biological treatment of rubber serum wastewater

Serum water from cup lump rubber is the main cause of disturbing odors in rubber block factories and has a very high treatment cost. Therefore, a prototype of a serum water treatment system using a multi-step biological process was studied to decompose the rottenness and treat the odor, using more than 60% less energy than before. The water that passes through the system contains microorganisms that can be used to wash rubber piles to reduce disturbing odors. In addition, it is suitable as a soil amendment because it contains the amount of nitrogen, phosphorus, and potassium that plants need on average, more than 0.8, 0.5, and 0.7 kilograms per cubic meter, respectively. The results of the study resulted in appropriate parameters for remote control of the system and further development of a data set to be able to track and control the automatic system in the future. In the next step, it will be expanded to use in the company’s two branch rubber block factories this year, including the concentrated latex factory and the raw material purchasing center.

(The detail can be found in the 2024 Sustainability Report under the section on Innovation Management)